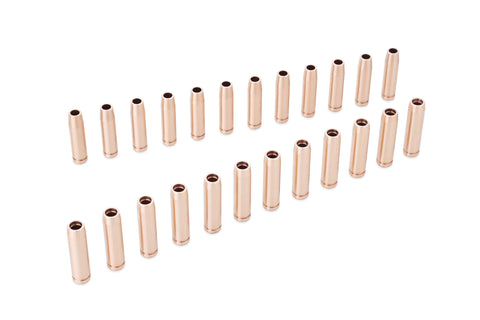

The Tomei Valve Guide Set for RB25 and RB20 engines is crafted using Phosphor Bronze (Cn-Sn-P alloy), a material renowned for its tensile strength and exceptional heat transfer properties. This makes it a crucial component for engines generating high power and operating at elevated RPMs. Modern race engines, which demand more power at higher RPMs, often face extreme heat conditions, leading to faster deterioration of valve train components. Tomei’s use of Phosphor Bronze ensures that these valve guides offer lower friction and maintain precise clearances, reducing stress on the entire valve train assembly and preventing potential issues like seizures or cracking under heavy stress loads.

Despite their durability, these valve guides still require regular maintenance when used in extreme conditions. Aggressive camshafts, lateral pressure from rocker arm assemblies, and carbon buildup are just a few factors that can accelerate wear and tear. Improper seat cuts or clearance issues can also contribute to faster degradation of the valve guides. Maintaining the correct clearance and performing regular inspections can help extend the life of these components.

At Terra Firma Automotive, we provide high-quality Tomei Valve Guide Sets to ensure your RB25 or RB20 engine runs smoothly and efficiently, even in the most demanding racing environments.

- The rocker arm type assemblies will apply more lateral pressure, which will increase the wear rate. If the stem wall of the valve is rough, it will also contribute to the increased wear rate.

- Using high lift, aggressive camshafts will also increase the wear rate.

- Excessive buildup of carbon will also hinder performance and increase wear rate. When there's a small opening at the end, it will increase the carbon buildup rate as a funnel effect.

- The results from Valve Spring surging will cause the Valve to move on an angle. This will cause both ends to open up and create deformation. Then carbon can enter the valve guides more which will increase the wear rate.

- A defective seat cut. When the seat cut's centerline across the main 45 degree face is offline from the valve stems centerline by more than 0.01mm, this can cause increased abnormal wear rate.

- If the clearance is not within the correct 0.03-0.04mm range. The Valve will rub against the guides inner wall, this degree angle in relation to the seat cut will cause it to shift by 0.01mm more than the clearance values. The guide will take the lateral pressure point and open up the opening. The buildup of carbon will increase in the newly formed gaps.

- A worn out used Valve. It's possible to cut down by using the part that has not worn out the stem when changing to a high lift cams. The guides can wear out when the inappropriate clearances are made. (About 0.01mm out of clearance).

- The Valve design is defective. The difference from the dilatability and the guide being worn out abnormally is when the valve that is made with different alloys, will contribute with a faster deterioration.

Questions & Answers

Have a Product Question?

Be the first to ask a question about this part.